Design office – Methods

- Home

- DO methods Control

- Design office – Methods

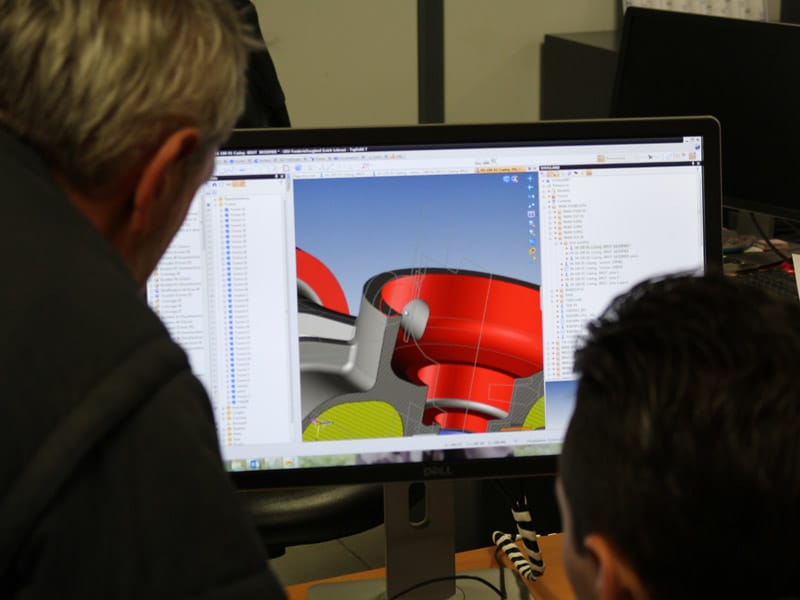

Our expertise and design resources, combined with our experience as foundrymen enable us to perform and validate the transition from the design phase to the production phase.

Our cast iron and steel design office analyses the feasibility of your request or your specifications (an idea, a part, a plan, a file, etc.) by anticipating the technical restrictions of your project and the necessary resources. We provide you with a comprehensive solution that integrates the estimated costs, quality restrictions, scheduling, technical and economic context, etc...

To ensure the quality of your parts, our design team covers every stage of the project up to final validation before marketing.

Digital design and simulation enable us to produce parts with a maximum level of compliance.

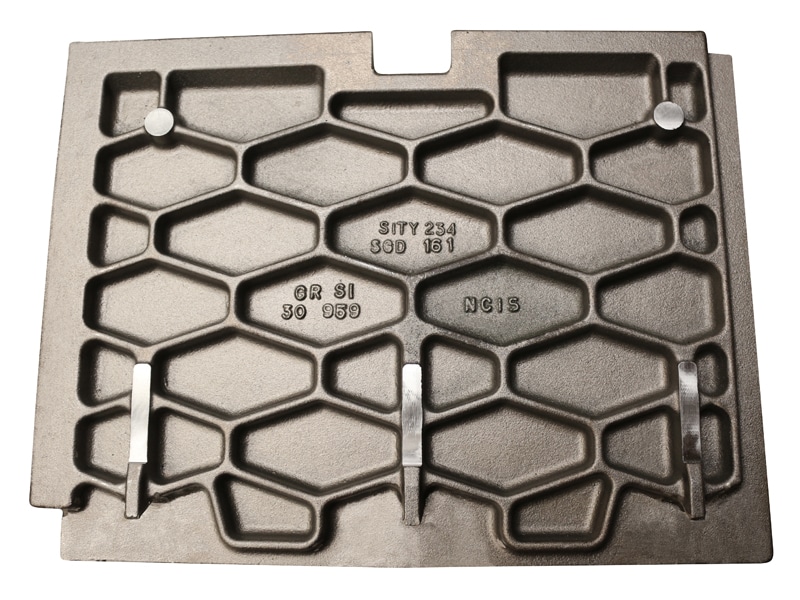

Furthermore, validation of the physical parts is essential. Our tests meet the most stringent requirements in terms of compliance.

Our prototyping solutions enable us to produce prototype parts in a very short space of time.

Tools can be produced by CNC-polystyrene milling, by stereo-lithography or by 3D printing.